Preventing Image Burn-In On Your Display

You are here

If you've ever left your LCD monitor on a single static screen for an extended period, say 24 hours or more, and then changed the on-screen image and seen a "ghost" of the previous screen, you've experienced Image Persistence. You can also sometimes see this phenomenon while traveling through an airport and seeing the flight status monitors. The good news is that the persistence is not permanent, unlike previous technologies such as plasma displays or CRTs.

The previous technologies of plasma displays and CRTs are phosphor-based, and extended static images create a "burn-in" that affects the properties of the phosphor material and create permanent damage. The damage is called burn-in, whereas static image "ghosts" on an LCD are Image Persistence. Image Persistence is not permanent damage and is reversible. Modern LCDs include design, driver ICs and chemical improvements that minimize these effects.

Image persistence can happen with any LCD panel, and almost all specifications will have some reference to image persistence. Many will have a specific criterion of acceptable levels of it.

Why does Image Persistence happen?

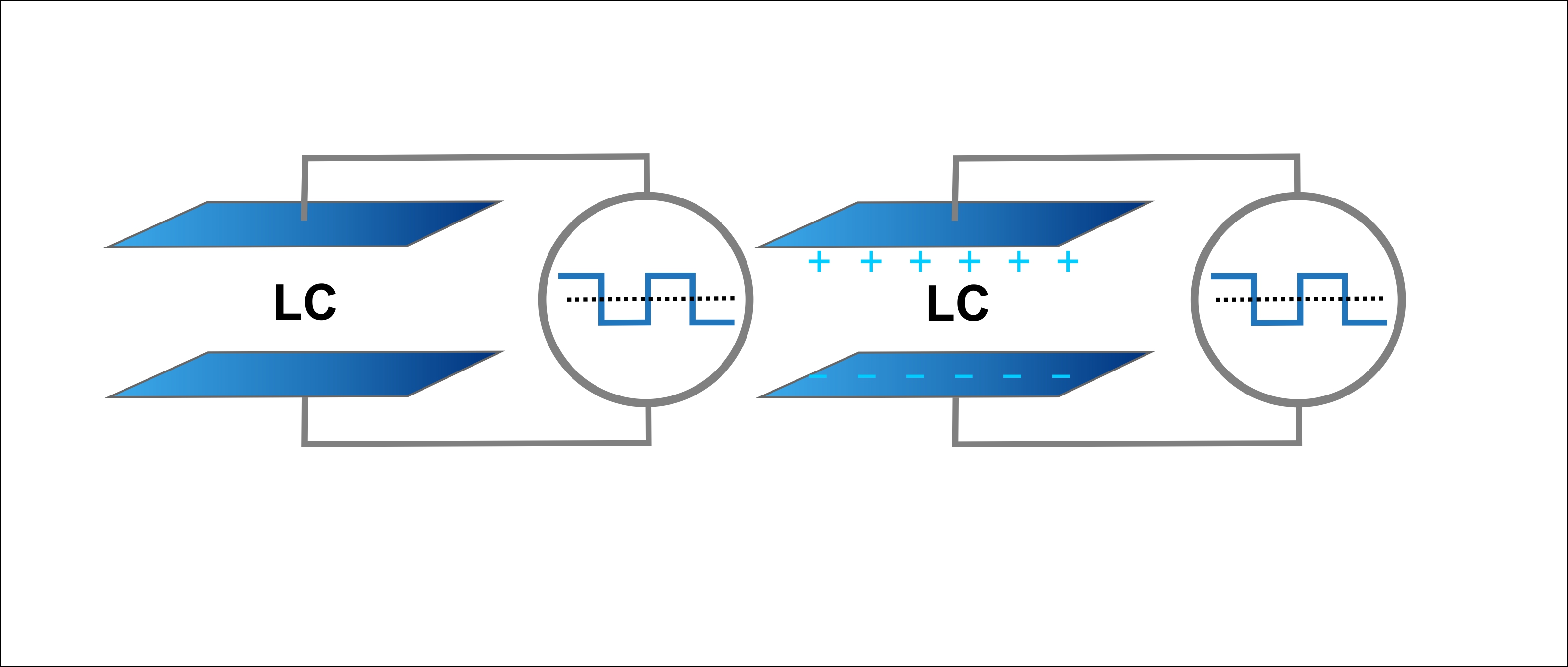

To understand why image persistence happens, we must first understand the basic structure of an LCD TFT. Within the TFT, a voltage is applied to the liquid crystal material to align or twist the crystals in each pixel to allow light to pass through or block light, thus creating the on-screen image. By allowing a static image to remain on screen for an extended duration, the polarity of that voltage on the crystals remains. During this time, ions within the liquid crystal fluid will migrate to either the + or – electrode of the transistor (source or drain). As these ions accumulate on the electrodes, the voltage applied to the crystals to align or twist is no longer sufficient to completely change the image on-screen, resulting in a "ghost effect" from the previous image.

Means to prevent or reduce Image Persistence

The best method for preventing Image Persistence is to avoid having any static images on the screen for an extended time. If the image changes periodically, the ion flow will never have an opportunity to accumulate on any internal electrode. However, depending upon the use of the display, it is not always possible to avoid static images on the screen. In cases such as these, there are steps that you can do to reduce the chance of persistence.

- Avoid static and long-time unchanging information and pictures.

- Switching off the display during periods of inactivity (sleeping mode) and arousing at necessary image changes would also be reflected as a positive side effect providing lower power consumption.

- Use a screensaver with a black or medium gray background automatically set to come on if the device is inactive for more than 5-10 minutes.

- Define icons, buttons, or windows utilizing block patterns instead of distinct lines as borders for dividing the display into different areas.

- Use a gradient approach to use symmetric to the middle grey level at the boundary of two different colors.

- Utilize medium gray hues for areas with prolonged images or remain static as other menu elements change.

Recovery methods

- Change the liquid crystal polarity to keep the ions moving freely.

- Free moving ions can minimize DC residue.

- Driving the whole background to black could eliminate ion accumulation that causes "washout image sticking."

- "Power off" for a prolonged time. The concentrated ions will diffuse naturally throughout the LCD cell.

Display technology has matured significantly over the past 20 years, and image persistence problems are far less common than in LCDs' early adoption.

Panel manufacturers specifically test for the phenomenon and have designed the TFT cell and improved the purity of the liquid crystal fluid to minimize any effect of image persistence.

If you have a project that is considering taking advantage of any display technology, US Micro Products can provide a solution designed for your application. Send us an email at sales@usmicroproducts.com.